Exploring the Different Types of Twin Screw Extruders

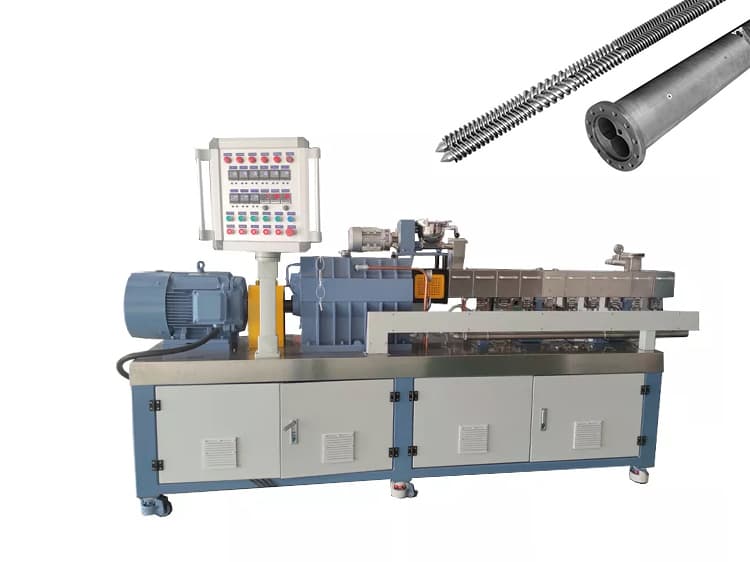

The Twin Screw Extruder is a highly efficient and versatile machine used in modern plastic processing. With two intermeshing screws rotating either in the same or opposite directions, it provides superior mixing, plasticizing, and compounding performance. Whether it’s the Co-rotating Parallel Twin Screw Extruder, Counter-Rotating Parallel Twin Screw Extruder, or Conical Twin Screw Extruder, each design offers unique advantages to meet specific production requirements. From PVC pipes and profiles to high-performance engineering plastics, these extruders deliver consistent quality, stable output, and long-term reliability—making them the preferred choice for manufacturers seeking precision and productivity.

In the world of plastic processing, twin screw extruders are the real workhorses. Whether it’s compounding, pelletizing, or profile extrusion, these machines ensure consistency, high output, and excellent material mixing. But not all twin screw extruders are the same. They come in several designs, each with unique screw configurations and rotation modes that affect performance, mixing efficiency, and final product quality. Let’s take a closer look at the main types and what makes each one stand out.

1. Co-Rotating Parallel Twin Screw Extruder

The Co-rotating Parallel Twin Screw Extruder is perhaps the most common type in modern compounding applications. In this design, both screws rotate in the same direction, creating a self-wiping action that ensures excellent material exchange and uniform mixing. Because of its high-speed operation and efficient heat transfer, it’s widely used for producing engineering plastics, masterbatches, and other high-performance polymer blends.

What makes this type especially popular is its flexibility—it can handle a wide variety of materials, from high-viscosity thermoplastics to delicate additives that require gentle treatment.

Advantages of Co-rotating Twin Screw Extruders:

- Enhanced Mixing: The intermeshing screws, along with customizable screw elements, enable precise control over mixing intensity and quality, surpassing single screw extruders.

- Processing Flexibility: Metered feeding allows for independent control of output, facilitating diverse processing functions on a single machine.

- Controlled Process Parameters: Narrow residence time distribution and precise temperature control result in improved shear-time-temperature profiles and better product quality stability.

- Efficient Production: Positive displacement conveying handles a wide range of materials with minimal downtime.

- Cost-effectiveness: High flexibility and productivity enable production of a variety of end products with consistent quality, while screw wear can be compensated by adjusting screw speed.

2. Counter-Rotating Parallel Twin Screw Extruder

As the name suggests, in a Counter-Rotating Parallel Twin Screw Extruder, the screws spin in opposite directions. This configuration prevents the material from forming an “∞” shaped movement, as the helical path of one screw is obstructed by the flights of the other screw. Instead, the material is conveyed forward in an approximately closed “C” shaped chamber during solid conveying. However, a certain gap is maintained between the outer diameter of one screw and the root diameter of the other screw to allow material passage. This configuration generates a more stable and consistent pressure in the processing section, making it ideal for PVC pipe, profile, and sheet extrusion.

Compared with co-rotating models, counter-rotating extruders typically run at lower speeds but deliver greater torque. This makes them perfect for applications that require precise temperature control and high material density. The design also minimizes shearing, protecting heat-sensitive materials during processing.

3. Conical Twin Screw Extruder

The Conical Twin Screw Extruder features two conically shaped screws that taper toward the end. This design offers a larger feeding area and a stronger compression ratio, which enhances material plasticization and mixing. It’s particularly well-suited for PVC products like pipes, profiles, and sheets.

One of its main advantages is the excellent torque distribution due to the conical geometry, which reduces mechanical stress on the gearbox and screw shafts. Additionally, its compact structure and efficient temperature control make it an energy-saving and cost-effective choice for many manufacturers.

The two conical screws are horizontally arranged, with their axes angled upon insertion into the barrel. As the distance between their axes gradually increases from the narrower end to the wider end, the transmission gearbox accommodates larger center distances between the two output shafts. This arrangement allows for ample space for the installation of gears, gear shafts, and radial and thrust bearings, facilitating efficient transmission.

This design flexibility enables the incorporation of larger radial and thrust bearings, with shafts adequately sized to handle high torque transmission. Consequently, conical twin screw extruders exhibit remarkable characteristics, including high working torque and load-bearing capacity, distinguishing them from parallel twin screw extruders.

Choosing the Right Twin Screw Extruder

Selecting the right extruder type depends on your production needs. If your focus is on high-performance compounding, a co-rotating parallel design is the go-to. For stable pressure and precision with PVC products, the counter-rotating type is ideal. Meanwhile, for enhanced torque and efficient melting, the conical design offers excellent value.

No matter the choice, each type of twin screw extruder plays an essential role in modern plastic processing, pushing innovation and productivity to new levels. Understanding their differences helps manufacturers make smarter investments—and get the best possible results from their extrusion lines.